testing by torsion steel ck45|ck45 welding joints : dealers Tensile tests were carried out at room temperature by using DARTEC testing machine with a capacity of 20 KN at a testing rate of 0.25 mm/sec in order to evaluate the . Resultado da 16 de nov. de 2001 · Principal HD. Assistir Harry Potter e a Pedra Filosofal Online. Uma jornada além de sua imaginação. Nov. 16, 2001 UK, USA .

{plog:ftitle_list}

Depende do tema. Neste caso, estamos a falar de um assunto ligeiro: A chave premiada de um jogo de sorte. O psicólogo Tiago . Ver mais

Tensile tests were carried out at room temperature by using DARTEC testing machine with a capacity of 20 KN at a testing rate of 0.25 mm/sec in order to evaluate the . When it comes to versatile, durable carbon steels, CK45 steel stands out as a popular choice across a wide range of industries. Known for its balanced composition, high . Spheroidizing annealing and torsion testing of 0.027 wt% carbon steel rod were conducted to evaluate spheroidization kinetic behavior at 943 K (670 °C) under deformed and non-deformed states. Kinetic curves were also predicted using the Johnson–Mehl–Avrami–Kolmogorov equation, and the results agree well with the experimental . The results obtained from the tensile test indicate that the tensile strength and total elongation of the crankshaft material are within the acceptable range of standard material. However, the yield strength is about 34 % lower than the high limit of standard steel material (CK45 / DIN 1.1191 steel). 3.

When it comes to versatile, durable carbon steels, CK45 steel stands out as a popular choice across a wide range of industries. Known for its balanced composition, high strength, and excellent machinability, CK45 is frequently used in applications where wear resistance and strength are crucial. This guide delves into CK45 steel’s chemical composition, . For this purpose three group specimens of Stainless steel 304L and Carbon Steel investigated. After each test and using stable hysteresis cycles material parameters have been obtained for using in .is made to study the effect of robotic GMAW parameters on the strength of the weld metal in CK45 carbon steel. Materials and Methods The CK45 medium-carbon steel (according to the DIN-1.1191 standard) in the form of a plate with a thick-ness of 20 mm was used as a base material and the ER70S-6 (AWS-A5.18 Classification) wire electrode withEN 10083-2 C45 steel (EN 1.0503) is a high strength medium carbon quality steel. Due to poor hardenability, C45 material is generally used in a normalized condition, and when the mechanical properties are required to be high, the quenching and tempering treatment is adopted. The cold deformation plasticity is medium, and the machinability of .

A commercial CK45 steel with chemical composition (wt%) of Fe-0.476C-0.543Mn-0.274Si-0.094Cr-0.044Ni-0.019P-0.007S was used in this work. Based on the Kasatkin equations [43, 44], the critical Ac 1 and Ac 3 temperatures were estimated as ~ 729 °C and ~784 °C, respectively.The initial martensitic sheet was obtained by annealing at the austenitization . Specimen for tension-torsion fatigue test at ultrasonic frequencies in very high cycle fatigue. The cruciform specimens, as shown in Fig. 8 [16], . the maximum normal stress σ n,max and the Findley parameter on different plane θ for the steel Ck45 under loading case 1. The maximum where the Findley damage parameter is achieved can be .In this paper, the plastic behavior of steel CK45 is declared with the help of combined hardening model. Chaboche nonlinear kinematic hardening model as well as Voce isotropic hardening model were . Introduction To put meaning to the data and conclusions drawn in this experiment several things must be known about the materials tested and the theory behind torsion testing. The two materials tested, cast iron and mild steel, have opposing characteristics. Steel is classified as a ductile material, a ductile material is known to be able to experience very large .

Torsion testing is a type of mechanical testing that evaluates the properties of materials or devices while under stress from angular displacement. Torsion testing can be split into two distinct categories: testing raw materials like metal wires or plastic tubing to determine properties such as shear strength and modulus, or functional testing . In the present paper, a method for reliable estimation of defect profile in CK45 steel structures is presented using an eddy current testing based measurement system and post-processing system . Ck45 steel is a commonly used material in structural engineering due to its excellent mechanical properties and suitable chemical composition. Understanding these aspects helps to explain why it is an ideal choice in structural engineering. Mechanical Properties: Ck45 steel exhibits high strength and good toughness, making it suitable for structural applications .

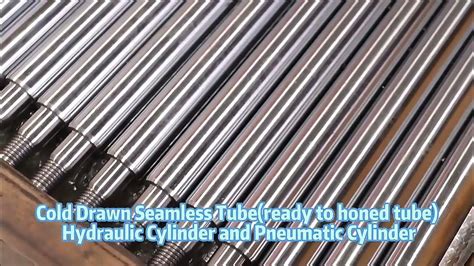

Check the SAE 1045 Steel Chemical Composition, AISI 1045 offers high strength and good weldability. . Ck45 Steel Annealing. Aspect Details; Purpose of Annealing: Softens surface hardness for improved machinability: . Torsion bars: Connecting rods: Hydraulic clamps: Categories Uncategorized Post navigation. Welded Fittings. ASA 150 Flange Chart.

ck45 welding joints

Understanding Torsion TestingIn the field of mechanics and materials science, torsion testing is a crucial method for assessing the strength and behavior of materials under twisting forces. This comprehensive guide will provide an in-depth understanding of torsional testing, the machines used, and their applications in evaluating the performance and reliability .AISI 1045 Carbon Steel G10450 \ Din CK45 W-Nr. 1.1191 JIS S45C Sheet Plate . bolts, forged connecting rods, crankshafts, torsion bars, light gears, guide rods etc . Supply Form of AISI 1045 Carbon Steel G10450 \ Din CK45 W-Nr. .based damage accumulation enhances the predictability of the fracture onset when the materials enduring torsion-tension loading. In a similar study, low cycle fatigue behavior of steel samples in addition to the response of low cycle creep- . Monotonic stress-strain curve of steel CK45 obtained from tensile test. Table 1. Mechanical .

Torsion Test on Mild Steel. In torsion testing the circular bar is placed in the machine such a way that its longitudinal axis coincides with the axis of the grips and so that it remains straight during the test. Then rotate one grip at a reasonable constant speed until the test piece breaks, here the shearing stresses will develop in any cross .vii Contents Foreword v Contents vii summary ix IntroduCtIon 1 1.1 Torsion of beams 1 1.2 Scope of this publication 2 1.3 Terminology and symbols 3 1.4 References to Eurocode 3 4 elastIC theory oF torsIon 7 2.1 St Venant torsion 7 2.2 Warping torsion 9 .The torsion test is a mechanical test method used to examine the deformation of a specimen through a twisting/rotating motion.. Torsion, in its simplest form, is the action of twisting. Many everyday materials, components, component assemblies, and end-user products used in various industries are designed with the primary purpose of supporting this direction of movement.Download Table | Combined tension-torsion data for En8 steel from publication: Elastic strain energy density decomposition in failure of ductile materials under combined torsion-tension | The .

Arc narrow gap welding of the 35L carbon cast steel (cast carbon steel J03502, grade 1) and the 110G13L high-manganese steel (austenitic manganese steel, ASTM A128) is performed using chromium . Fatigue behavior and mechanical properties of CK45 mild carbon steel has been investigated under combined heat treatments processes. The 80 standard samples were machined, quenched and tempered at . Next, S–N diagram of CK45 carbon steel considering surface roughness of 2.07 microns was predicted using the proposed model and different orders (first-, second-, and third-order regression).AISI 1045 steel is a medium tensile steel supplied in the black hot rolled or normalized condition. It has a tensile strength of 570 - 700 MPa and Brinell hardness ranging between 170 and 210. . Torsion bars: Hydraulic clamps: This article was updated on 7 th August, 2019. Download PDF Copy; . Mechanical & Physical Properties Testing

Introduction. Torsion test is carried out to determine the shear modulus of structural materials, such as steel and aluminum. Shear modulus is a material property that is useful in calculating the compliance of structural materials in torsion, provided that they follow Hooke’s law; that is, that the angle of twist is proportional to the applied torque.EN8 Steel (BS970 080M40 Material) En8 steel was renamed 080M40 in 1970. It is a commonly used medium carbon engineering steel with good mechanical properties and is widely used in the manufacture of mechanical parts, such as general axles and shafts, gears, bolts and stud bolts. The standard for this steel is BS970, first published in 1941.

ck45 weld strength

Resultado da 14 de mai. de 2023 · Descargar Traffic Rider apk hack dinero infinito mediafire 2023. Traffic Rider todo desbloqueado lleva el género de .

testing by torsion steel ck45|ck45 welding joints